The process of loading shipping containers encompasses three primary methods: manual filling, slip sheet use, and pallet loading. Manual filling, or handballing, involves workers physically placing items inside the container. The slip sheet method employs thin cardboard or plastic sheets under the goods, enabling easier movement and arrangement within the container. Pallets are another popular option, where goods are stacked on pallets and then loaded using equipment like forklifts. Each of these methods has its benefits and is chosen based on the nature and volume of the cargo being shipped.

In the complex world of logistics, the loading of shipping containers is a critical process. There are three main methods for filling sea containers: manual filling, slip sheet use, and pallet loading. Manual filling, commonly referred to as handballing, involves workers manually placing and arranging items inside the container. This method is often used for smaller, manageable loads or when precision placement of goods is required. Slip Sheets, thin sheets of cardboard or plastic, are placed beneath goods to facilitate easy movement and arrangement inside the container. Pallet loading is a more mechanized approach, where goods are first stacked onto pallets and then loaded into the container using equipment like forklifts. These methods are essential to maximize space efficiency and ensure the safety of goods during transportation.

The Importance of Proper Container Loading

Container loading requires careful planning, precision, and years of experience. Always use space efficiently to ship more goods in one shipment, lowering shipping costs. Expertly packed and stabilized goods are less likely to shift or move during transit, reducing the risk of damage. Thus, optimal container loading saves shipping companies money and improves cargo safety.

More broadly, proper container loading helps the environment. Maximizing container space may reduce shipments, fuel consumption, and carbon emissions. It streamlines port operations because properly loaded containers speed up loading and unloading, reducing ship idle time. Thus, container loading is crucial to green shipping and operational efficiency.

The Role of Port Workers in Container Loading

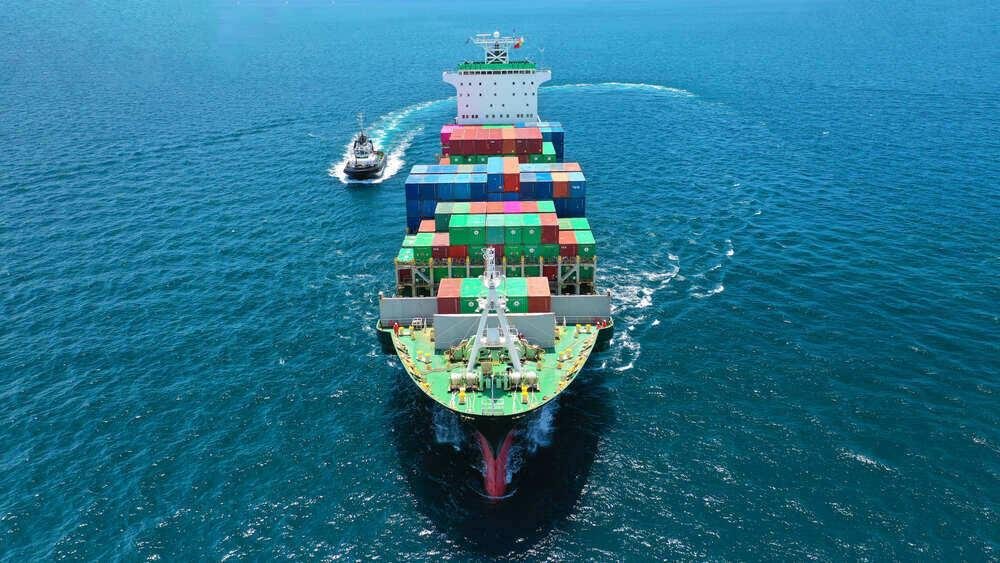

International trade relies on shipping containers, massive structures used to transport goods. Port workers make sure their loading and unloading go smoothly. Port workers are the gears of container loading, affecting trade and the global economy.

Port workers show their best skills during container loading. They must carefully load containers onto ships using heavy machinery, taking into account weight, fragility, and ship logistics. A single mistake could result in damage, loss, or disaster at sea, so this complicated process requires precision and expertise. In global trade logistics, port workers are unsung heroes who ensure safety and efficiency.

Types of Equipment Used for Container Loading

In the logistics industry, various pieces of equipment play crucial roles in container loading, ensuring safe and efficient operations. Foremost among these are the towering gantry cranes; these giants dominate the skyline of major ports worldwide. Characterized by their burgeoning height and robust stature, they are responsible for moving and stacking the heavy containers. They are configured with a spreader, which can adjust to the size of the container, facilitating the quick, precise, and secure movement of containers.

Another essential piece of kit is the reach stacker. This equipment is versatile and designed for flexibility, enabling it to handle containers with varying dimensions. Its capabilities extend from straightforward tasks like container transport to more complex operations that include container stacking. Forklifts are also standard at ports for handling less-than-container load shipments. They assist in moving smaller crates, pallets, and containers around the harbor. Understanding these tools gives one a deeper insight into how equipment and machinery shape the container loading process.

Frequently Asked Questions

The container loading process involves arranging and securing cargo within a container in preparation for shipment. This process often consists of using various types of equipment to move and secure the load.

Proper container loading is crucial for the safety of the cargo, the container, and the shipping vessel. It ensures that the shipment is secure during transport, preventing damage and adding to the efficiency and effectiveness of the shipping process.

Port workers play a vital role in container loading. They operate the equipment used to load containers, meticulously place the cargo in an order that optimizes space and maintains the stability of the container, and secure the cargo to prevent movement during transit.

Various types of equipment are used in container loading, including forklifts, cranes, and straddle carriers. These machines move the cargo into the container, while tools like lashings and dunnage are used to secure the load.

While some equipment, like forklifts and cranes, are often used for various cargo types, certain types of cargo may require specialized equipment. For example, refrigerated freight may require specialized equipment to maintain the temperature within the container.

Share on Facebook

Share on Facebook Share on LinkedIn

Share on LinkedIn Share on Twitter

Share on Twitter

Google

Google  Instagram

Instagram  Trustpilot

Trustpilot