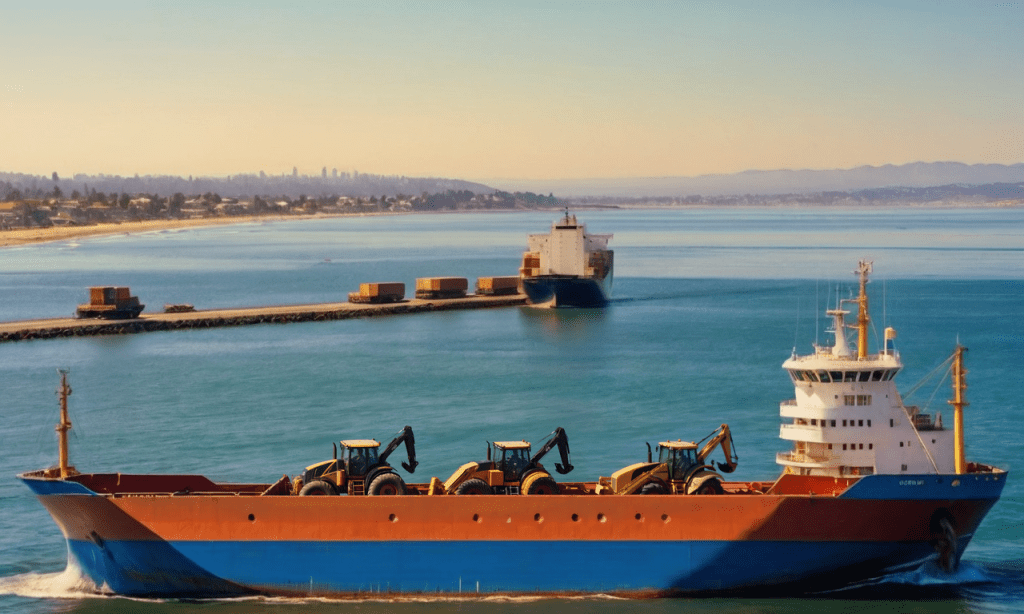

When it comes to shipping heavy equipment, one critical decision can make all the difference - choosing the right size of container. Whether you're moving construction machinery, industrial equipment, or any sizable gear, the container you pick can impact the safety, cost, and success of your shipment.

So, how do you make the right choice? In this comprehensive guide, we'll provide you with the knowledge and insights you need to guarantee your heavy equipment arrives at its destination intact and on time. We'll answer the fundamental question: "How do I choose the right size of container for shipping heavy equipment?"

Shipping heavy equipment isn't as straightforward as sending a parcel, and selecting the wrong container size can lead to damage, delays, and added expenses. That's why we've put together this article to help you navigate the intricacies of container selection. By the end, you'll be equipped with the expertise to make informed decisions, ensuring a smooth and successful shipping process for your valuable heavy equipment. Let's get started.

Understanding Your Heavy Equipment

Before delving into the specifics of shipping containers, it's important to understand your heavy equipment. Heavy equipment comes in various shapes and sizes, from bulldozers and excavators to industrial generators and more. Each piece of machinery is unique, and its dimensions and weight vary significantly.

To select the right shipping container, you must start by thoroughly measuring and assessing your heavy equipment. Begin by noting down its length, width, height, and weight. These measurements will serve as the foundation for your container selection process.

Keep in mind that shipping containers come in different types, including standard, high cube, flat rack, and specialized containers like refrigerated or tank containers. Understanding the precise dimensions of your heavy equipment is important because it will determine whether it fits comfortably and securely within the chosen container.

Accurate measurements are the key to a successful heavy equipment shipment. Once you have a clear understanding of your equipment's size and weight, you can move on to selecting the most appropriate shipping container to guarantee a safe and efficient transit.

Types of Containers for Shipping Heavy Equipment

Now that you have a grasp of your heavy equipment's dimensions, let's explore the various types of containers available for shipping heavy equipment. Shipping containers come in diverse forms, each designed for specific cargo and purposes.

- Standard Containers: These are the most common type of shipping containers, available in 20-foot and 40-foot sizes. Standard containers are suitable for a wide range of equipment, especially when they fit within the container's dimensions.

- High Cube Containers: If your heavy equipment exceeds the height of a standard container, high cube containers offer extra vertical space. They are typically one foot taller, providing more room for taller machinery.

- Flat Rack Containers: When your equipment doesn't fit within the dimensions of standard containers, flat rack containers come to the rescue. They have collapsible sides, making them ideal for oversized or oddly-shaped equipment.

- Refrigerated Containers: For equipment that requires temperature control, such as perishable goods or sensitive machinery, refrigerated containers are equipped with cooling or heating systems.

- Tank Containers: These containers are designed for transporting liquids and hazardous materials safely. Tank containers have special features to prevent spills and leaks.

Understanding the types of containers available allows you to match your heavy equipment with the most suitable option. In the following sections, we will delve deeper into selecting the right size and dimensions of these containers to guarantee a successful heavy equipment shipping experience.

Choosing the Right Container Size for Your Shipping Needs

Now that we've covered the types of containers available, let's delve deeper into container sizes and how they relate to shipping heavy equipment.

The two most common container sizes are the standard 20-foot and 40-foot containers. These sizes are widely used for various cargo, including heavy equipment. When choosing a container size, it's important to consider the dimensions of your equipment.

- 20-Foot Container: This container size is suitable for smaller to medium-sized heavy equipment. It provides ample space for compact machinery while maintaining a manageable size for transportation.

- 40-Foot Container: If your heavy equipment is on the larger side, a 40-foot container might be the better choice. It offers twice the space of a 20-foot container, accommodating more extensive machinery comfortably.

However, it's important to take into account that container dimensions aren't the only factor to consider. You must guarantee that your heavy equipment fits inside without being overcrowded or causing any damage during transit. Adequate clearance around the equipment is necessary to prevent accidents and guarantee safe loading and unloading.

In some cases, high cube containers, which are one foot taller than standard containers, can provide the additional vertical space needed for taller heavy equipment. These containers are especially useful when your machinery exceeds the height limitations of a standard shipping container.

Understanding the available container sizes and types is a significant step toward choosing the right one for your heavy equipment. In the next sections, we'll explore weight considerations and specialized containers for unique shipping needs.

Necessary weight Considerations for Shipping Heavy Equipment Safely

When it comes to shipping heavy equipment, weight is a critical factor that can't be overlooked. Each shipping container has a maximum weight capacity, and exceeding it can lead to safety hazards and potential damage to your equipment.

To guarantee a smooth and secure shipping process, you must calculate the weight of your heavy equipment accurately. This includes not only the machinery itself but also any additional attachments, accessories, or fuel tanks that will be shipped along with it.

Before choosing a container, verify its weight capacity. Standard shipping containers typically have a weight capacity of around 24,000 kilograms (53,000 pounds) for a 20-foot container and 30,480 kilograms (67,200 pounds) for a 40-foot container. High cube containers have similar weight limits.

If your heavy equipment approaches or exceeds these weight limits, it's necessary to consider alternative options, such as flat rack containers. Flat rack freight containers are designed for oversized and heavy cargo. They offer sturdier support and higher weight capacities compared to standard containers.

Additionally, distributing the weight evenly within the container is critical to prevent tilting or tipping during transit. Proper blocking, bracing, and tie-downs are necessary for securing your heavy equipment within the container, ensuring its safe journey.

By carefully considering weight limits and distribution, you can select the right container and shipping method for your heavy equipment, minimizing the risk of accidents or damage during transportation.

Specialized Solutions for Shipping Heavy Equipment Safely

In some cases, standard container options may not suffice for shipping your heavy equipment. This is where specialized containers come into play, offering tailored solutions to meet unique shipping needs.

One such specialized container is the flat rack freight container, commonly referred to as a flat rack. Flat rack containers are designed for cargo that exceeds the dimensions or weight limits of standard containers. They feature collapsible sides, making them ideal for oversized or irregularly shaped heavy equipment.

Flat racks come in various sizes, including 20-foot and 40-foot options, similar to standard containers. However, their open design provides flexibility in accommodating heavy machinery with unconventional shapes or sizes. This versatility makes flat racks an excellent choice for shipping heavy equipment that wouldn't fit comfortably in a standard container.

Additionally, if your equipment requires specialized handling due to its unique characteristics, such as refrigeration or specialized ventilation, there are containers designed to meet these requirements. For instance, refrigerated containers, often known as "reefers," are equipped with cooling or heating systems to maintain specific temperature conditions.

When selecting a container for your heavy equipment, consider its individual specifications, dimensions, and any special requirements it may have. Specialized containers guarantee that your equipment reaches its destination safely and in the best possible condition, even when it deviates from standard shipping container sizes and types.

Packing and Securing Heavy Equipment

Selecting the right shipping container size and type is only the first step in ensuring the safe transportation of your heavy equipment. Proper packing and securing of the cargo within the container are equally necessary.

When loading heavy equipment into the container, it's necessary to:

- Use Proper Blocking and Bracing: Secure your equipment using suitable blocking and bracing materials to prevent shifting during transit. This is vital to avoid damage caused by movement inside the container.

- Tie-Downs: Utilize robust tie-downs to anchor your equipment firmly in place. These straps or chains will prevent any unintended movement during transportation.

- Consider Double Door Containers: If your heavy equipment is challenging to load through a single door, double door containers provide more flexibility for loading and unloading oversized cargo.

- Temperature-Sensitive Goods: If you're shipping temperature-sensitive goods, guarantee that your container has the necessary temperature control mechanisms, such as refrigeration units or insulation.

- Work with Freight Forwarders: Consider partnering with a reputable freight forwarder who specializes in heavy equipment shipping. They have the expertise to handle oversized cargo, select the right container size, and manage the logistics of container shipping.

Properly securing your heavy equipment inside the container not only prevents damage but also guarantee the safety of container ships and personnel involved in loading and unloading. By paying attention to these details, you can guarantee a smooth and secure transit for your valuable cargo.

Key Factors to Consider When Evaluating Expenses

Selecting the right shipping container size is not just about ensuring the safety of your heavy equipment; it also has cost implications. Container shipping costs can vary depending on several factors, and choosing the right container size can help you manage expenses effectively.

While larger containers, such as 40-foot or high cube containers, provide more space, they also come with higher shipping costs. Oversized containers may incur additional fees due to their dimensions and weight. It's important to strike a balance between container size and budget.

Consider the following cost considerations:

- Container Size: Evaluate whether the extra space in a larger container is necessary for your heavy equipment. Choosing a container that fits your equipment snugly without excess room can help reduce shipping costs.

- Container Type: Specialized containers, like tank containers or refrigerated containers, may have higher rental or shipping fees. Determine if your cargo necessitates these specialized options.

- Freight Forwarder Services: Working with a freight forwarder can provide cost-effective solutions. They have industry knowledge and can negotiate better rates with shipping companies.

- Customs and Duties: Be aware of customs duties and taxes that may apply to your cargo. Consult with experts to navigate these financial considerations.

Balancing the right container size with your budget is important. By making informed decisions, you can optimize your heavy equipment shipping process while managing costs effectively.

Expert Advice and Consultation

Choosing the right shipping container size for your heavy equipment can be a complex task, especially if you're dealing with oversized cargo or temperature-sensitive goods. In such cases, seeking expert advice and consultation is highly advisable.

Freight forwarders, logistics experts, and shipping professionals have in-depth knowledge of container shipping and can provide invaluable insights. They can:

- Assess Your Cargo: Experts can evaluate your heavy equipment's specific requirements and recommend the most suitable container type and size.

- Navigate Regulations: Shipping heavy equipment often involves compliance with various regulations and permits. Experts can guide you through the legalities of oversized cargo or specialized containers.

- Optimize Costs: Professionals can help you optimize your shipping costs by selecting the most cost-effective container size and negotiating favorable rates with shipping companies.

- Make sure Safety: Safety is paramount when shipping heavy equipment. Experts can advise on proper packing, securing, and temperature control measures to protect your cargo.

- Troubleshoot Issues: In case of any unforeseen challenges or issues during transit, experts can provide solutions and minimize disruptions to your shipping process.

By collaborating with experts and seeking their consultation, you can mitigate risks, make sure the smooth transport of your heavy equipment, and make informed decisions that align with your specific shipping needs. Their expertise is an invaluable resource in the department of container shipping.

Conclusion

Finally, selecting the right container size for shipping heavy equipment is paramount to the success and safety of your cargo. Throughout this article, we've explored the nuances of container types, sizes, weight considerations, and specialized options.

The key takeaway is clear: making an informed choice when it comes to your container can prevent damage, delays, and unnecessary expenses. Prioritize accurate measurements, weight distribution, and securing your equipment within the container.

To guarantee the safety of your valuable heavy equipment during transit, we encourage you to consult with experts, utilize proper packing techniques, and consider all cost implications. By doing so, you can guarantee a smooth and secure journey for your heavy machinery. Make informed decisions, and rest assured that your equipment will reach its destination intact.

Share on Facebook

Share on Facebook Share on LinkedIn

Share on LinkedIn Share on Twitter

Share on Twitter

Google

Google  Instagram

Instagram  Trustpilot

Trustpilot